High Breathability With Edging Filter Screen – Nonwoven Industry Comprehensive Guide

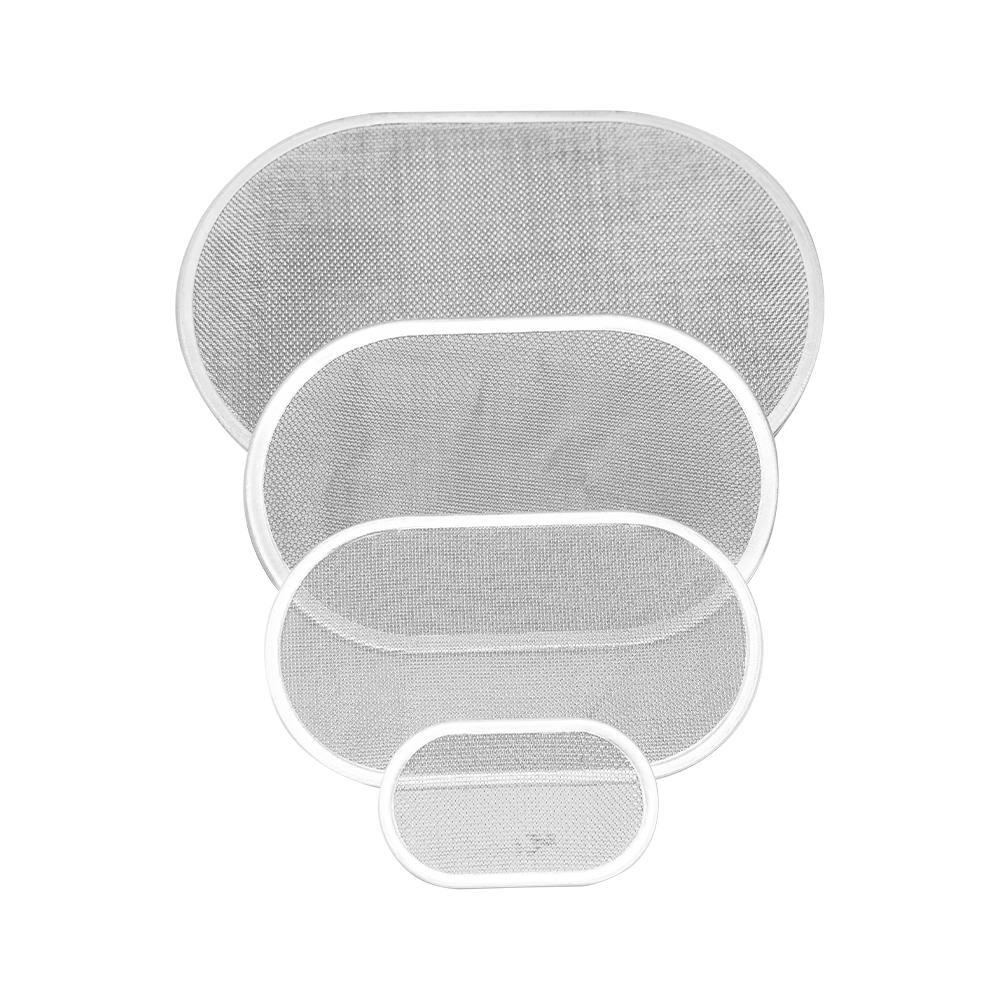

The High Breathability With Edging Filter Screen is a premium filtration solution widely adopted in the nonwoven fabric industry. Designed with reinforced edging and high-breathability mesh, it ensures consistent air circulation, reliable dust removal, and long-term durability. Its lightweight and easy-to-install construction makes it an ideal choice for nonwoven machinery, air filtration systems, and cleanroom applications.

This comprehensive guide covers packaging information, practical solutions, user guidelines, and upgrade options to help buyers, engineers, and maintenance teams maximize the performance and lifespan of the filter screen.

High Breathability Mesh: Ensures optimal airflow while maintaining effective particle filtration.

Reinforced Edging: Prevents fraying and maintains structural integrity under continuous operation.

Lightweight Construction: Easy to handle and install without additional labor costs.

Durable Material Options: Resistant to wear, chemicals, and temperature variations.

Customizable Sizes: Adaptable for various nonwoven machinery and cleanroom equipment.

Proper packaging is crucial to maintain the quality of the filter screen during transport and storage. The standard packaging details are as follows:

| Packaging Element | Description |

|---|---|

| Outer Packaging | Sturdy cardboard box or wooden crate |

| Inner Protection | Bubble wrap or anti-static protective film |

| Labeling | Product name, size, batch number, production date |

| Quantity per Package | 10–50 units depending on size and mesh type |

| Storage Instruction | Keep in a dry, clean environment; avoid stacking heavy objects |

Packaging Recommendations:

Use moisture-absorbent materials inside the packaging to prevent humidity damage.

Clearly mark the top and bottom of the package to ensure proper handling during transportation.

For international shipping, consider reinforced crates to avoid mechanical impact.

The filter screen provides high-efficiency dust removal and air circulation, essential for:

Spunbond, meltblown, and composite nonwoven production lines.

Preventing fiber contamination and ensuring consistent fabric quality.

Maintaining clean airflow in nonwoven manufacturing cleanrooms.

Ensuring compliance with industry standards for particulate control.

Installed in cyclone dust collectors or baghouse filters.

Enhances overall filtration efficiency and prolongs equipment lifespan.

Mesh size, edging material, and dimensions can be tailored to match specific machine models.

Optional coatings for chemical or heat resistance.

Preparation: Ensure the filter housing is clean and free from residual dust.

Positioning: Align the reinforced edges with the frame to prevent deformation.

Secure Fastening: Use clamps or screws depending on machine design.

Check Airflow: Verify unobstructed airflow after installation.

Regular Cleaning: Use compressed air or mild detergents. Avoid harsh chemicals.

Inspection: Check for fraying edges or mesh tears monthly.

Replacement: Replace damaged screens immediately to prevent operational inefficiencies.

Always wear protective gloves when handling the mesh.

Avoid bending or folding the screen to prevent permanent deformation.

Ensure machinery is powered off during installation or maintenance.

Aluminum or Stainless Steel Edging: For high-temperature or corrosive environments.

PVC or Reinforced Plastic Edging: Lightweight option for standard applications.

Anti-Static Coating: Prevents dust attraction and fiber accumulation.

Chemical-Resistant Coating: Suitable for exposure to cleaning agents or solvents.

For fine filtration in specialty nonwoven products, mesh can be customized from 10 to 500 microns.

Allows for easy replacement and reduced downtime.

Facilitates multi-stage filtration systems in large-scale production.

| Advantage | Benefit |

|---|---|

| High Breathability | Optimizes airflow, reduces energy consumption |

| Reinforced Edging | Prevents damage and extends lifespan |

| Lightweight Design | Simplifies installation and maintenance |

| Customization Options | Fits diverse machinery and applications |

| Cost-Effective | Reduces replacement frequency and labor costs |

The High Breathability With Edging Filter Screen is an essential component for modern nonwoven fabric production, providing reliable filtration, superior airflow, and durable performance. Its reinforced edging and lightweight design make it ideal for both standard and specialized applications. By following proper installation, maintenance, and upgrade guidelines, manufacturers can enhance productivity, maintain consistent product quality, and extend equipment lifespan.

Whether used in cleanrooms, air filtration systems, or dust collection units, this filter screen offers a versatile, high-performance, and cost-effective solution for the nonwoven industry.

This website uses cookies to ensure you get the best experience on our website.