Lightweight With Edging Filter Screen – Nonwoven Industry Comprehensive Guide

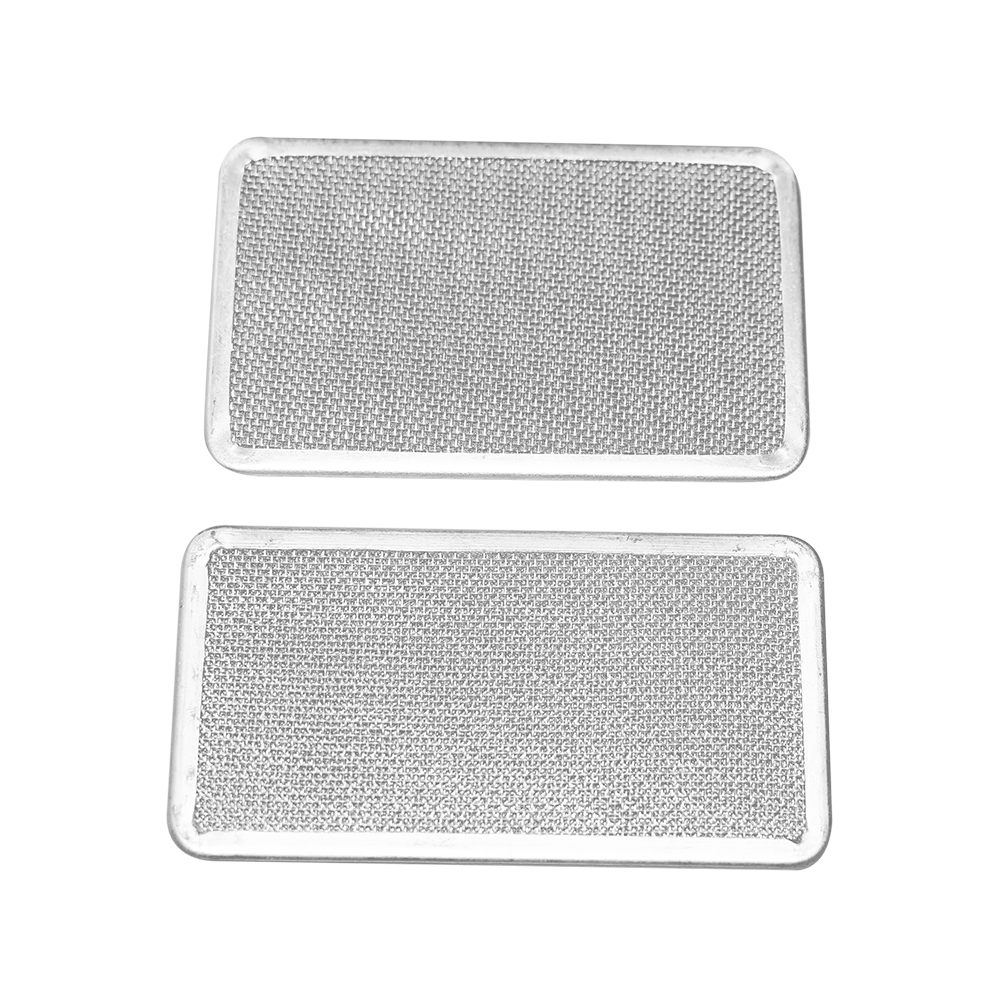

The Lightweight With Edging Filter Screen is an essential filtration solution designed specifically for the nonwoven industry. Combining a lightweight structure with reinforced edging, it ensures reliable performance, long-lasting durability, and consistent airflow. This product is widely used in nonwoven machinery, cleanrooms, and air filtration systems, providing efficient dust removal and improved process stability.

This guide provides a comprehensive overview of the product, covering key advantages, maintenance methods, repair procedures, and safety instructions to help manufacturers and maintenance teams optimize the performance of their filtration systems.

The reinforced edging prevents fraying, deformation, and premature wear, ensuring the filter screen maintains its shape and functionality over long-term use.

The lightweight construction allows for easy handling and installation, reducing labor costs and minimizing downtime during replacement or maintenance.

The high-quality mesh design ensures optimal air circulation, enhancing dust collection efficiency and maintaining consistent nonwoven fabric quality.

Air filtration in nonwoven production lines (spunbond, meltblown, composite fabrics)

Dust and fiber collection systems

Cleanroom airflow management

General industrial air filtration in nonwoven-related environments

Reduced replacement frequency and long service life result in lower operational costs, making it an economical choice for large-scale production lines.

Proper maintenance is critical to ensure the Lightweight With Edging Filter Screen performs optimally.

| Maintenance Step | Recommended Procedure |

|---|---|

| Cleaning Frequency | Weekly for high-dust environments, monthly for moderate-dust areas |

| Cleaning Method | Use compressed air, vacuum, or mild detergent for stubborn dust |

| Inspection | Check for frayed edges, mesh tears, or deformation before each cleaning |

| Replacement Criteria | Replace immediately if edges are damaged, mesh is torn, or airflow is restricted |

| Lubrication (if applicable) | N/A for mesh, ensure surrounding equipment is lubricated |

Tips for Optimal Maintenance:

Avoid harsh chemicals that may degrade the mesh or edging.

Do not bend or fold the screen during cleaning to prevent permanent deformation.

Maintain a clean working environment to reduce contamination and dust buildup.

Even with durable construction, occasional repairs may be required to extend the filter screen's lifespan.

Inspect the mesh for holes, tears, or clogging.

Check the edging for fraying or detachment from the mesh.

Small mesh tears can sometimes be patched with a compatible adhesive or mesh patch.

Frayed edging may be reinforced with edge tape or stitching.

For severe mesh damage or structural deformation, replacement is recommended.

Ensure replacement parts match the original specifications to maintain performance.

Clean the filter housing before reinstalling the repaired or replaced screen.

Secure the screen evenly to prevent airflow bypass and ensure stable operation.

To protect personnel and ensure operational safety, follow these guidelines:

Handling Safety

Wear protective gloves to avoid cuts from sharp mesh edges.

Handle screens carefully to prevent bending or damaging the reinforced edges.

Installation Safety

Ensure machinery is powered off before installation or removal.

Verify the screen is properly aligned and secured to prevent dislodgement during operation.

Operational Safety

Do not exceed recommended airflow or pressure limits.

Avoid exposure to corrosive chemicals unless the filter screen is specifically rated for such use.

Maintenance Safety

Use appropriate cleaning tools and avoid excessive force.

Regularly inspect screens and replace damaged units promptly to prevent system inefficiency.

| Parameter | Value |

|---|---|

| Material Options | Stainless steel, polyester, nylon |

| Mesh Size Range | 10–500 microns |

| Edging Material | PVC, aluminum, stainless steel |

| Weight | Lightweight (varies by size) |

| Operating Temperature | -20°C to 120°C (depending on material) |

| Customization Available | Yes (size, shape, edging type) |

The Lightweight With Edging Filter Screen is a reliable, high-performance solution for the nonwoven industry, offering:

Durable construction with reinforced edging

Lightweight design for easy handling and installation

Efficient air circulation and dust removal

Versatility across various nonwoven machinery and cleanroom applications

Cost-effective maintenance and long-term usage

By following the proper maintenance, repair, and safety procedures, manufacturers can maximize the lifespan and performance of the filter screen. This ensures consistent product quality, operational efficiency, and reduced downtime in demanding nonwoven production environments.

This website uses cookies to ensure you get the best experience on our website.